100+ years of successfully serving foundries.

Products

Products

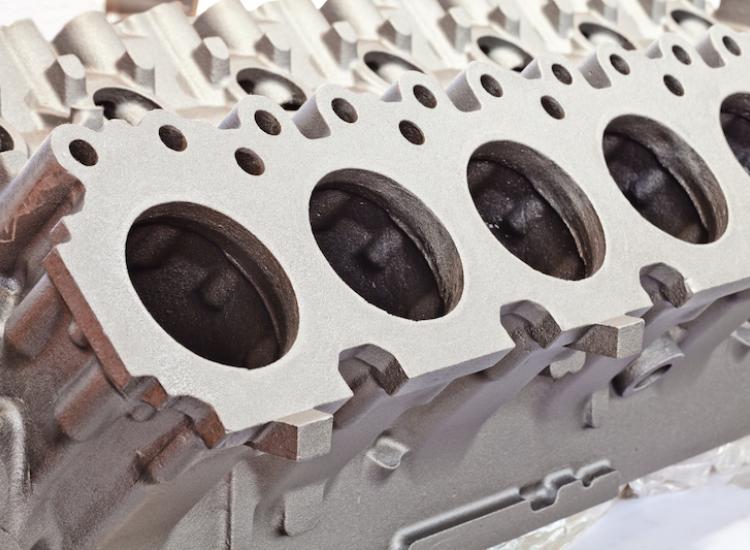

Wide array of products meet AFS standards

- ISO 9001 registered laboratories ensure product quality and consistency

- Highly packable, narrow particle distribution sands with high silica content

- Long history of high performance in challenging applications

- Ideal for foundry molding and core making applications

Product Selection

Product Selection

Many choices to meet the most exacting specs

- More than 25 grades of round and sub-angular foundry silica sands available

- Blending capabilities create even more size options

- Proven ability to fine-tune grades to create tighter particle size distributions

- Compatibility with all foundry binder systems

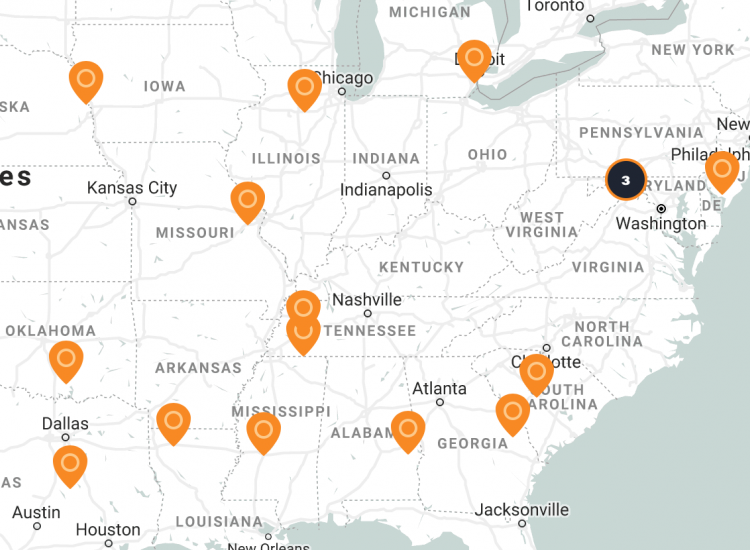

Locations

Locations

Strategically Located Plants

- We’re located near the best available mineral resources

- Multiple plant locations minimize freight costs and speed delivery time

- Diversity of plant locations helps ensures reliable, uninterrupted shipments

Sil-Co-Sil®

The high-purity content of our SIL-CO-SIL ground silica (at least 99.5% Si02) helps ensure consisten...

EverWhite™

Durable, high temperature resistant silica additive for countertops and investment casting.

Whole Grain Silica for Foundries

Whole grain silicas specially processed to create high-integrity castings.

Celatom® MN Grades

MN grades are used in agriculture, home & garden, automotive components, ceramic and fertilizer indu...

Celatom® MP Grades

Used in industries like agriculture, oil & gas, fracking, industrial, fertilizer, environmental reme...