Over 100 years of successfully serving the glass industry.

Choose from an array of chemistries and particle size distributions. Or have us create your custom blend.

Product Quality

Product Quality

High-purity consistent products

- High-quality sands with few impurities enhance operational consistency

- Daily product testing ensures consistency in chemistry and sizing

- Low-iron sands can be further refined through flotation or magnetic separation

- Special processing techniques and grinding capabilities control particle size

Product Selection

Product Selection

Broad offering, customized solutions

- Low-iron options optimize color and clarity

- High-aluminum options available for increased durability

- Combination of high-aluminum and low-iron products optimize processing

- Some of the whitest and brightest sands found on the market

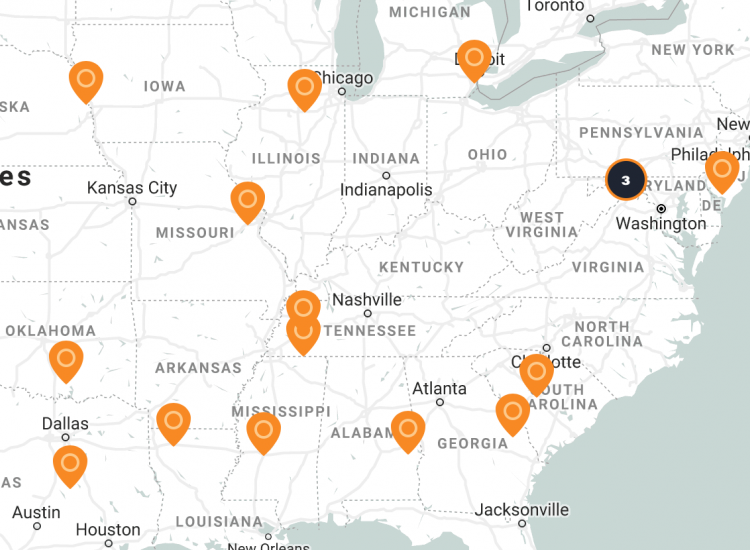

Locations

Locations

Everywhere you need us

- Strategically located plants minimize freight costs and speed delivery time

- With so many plants and products, chances are we have exactly what you need

- Diversity of plant locations helps ensure reliable, uninterrupted shipments

Research & Development

Research & Development

Strong Reputation for innovation

- More than a mining company; we’re not limited to what comes out of the ground

- Ongoing research continues to improve product performance

- We understand the unique challenges of glass manufacturing and know how to adapt

Applications

Multiple glass silica grades and aplite grades available to enhance performance in a wide array of glass applications, including:

Explore Glass Products